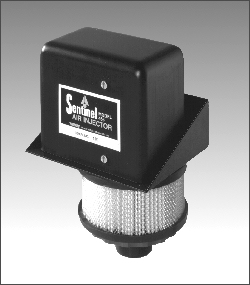

The Sentinel Air Injector is a time adjustable, variable flow air injector used in the wash-up process of dairy farm milking systems. The Sentinel Air Injector produces slug flow in the pipeline in order to increase the circulating velocity of the cleaning solution and also reduce the water requirement. The proper sizeand speed of the slugs are controlled by a combination of the air injector's open and closed time and its adjustable air intake sleeve. The two potentiometers controlling the open and closed time can be set to a maximum of 30 seconds each. The air intake sleeve can be adjusted to intake between 20 and 120 CFM of air at 15 inches Hg. The Sentinel Air Injector is a time adjustable, variable flow air injector used in the wash-up process of dairy farm milking systems. The Sentinel Air Injector produces slug flow in the pipeline in order to increase the circulating velocity of the cleaning solution and also reduce the water requirement. The proper sizeand speed of the slugs are controlled by a combination of the air injector's open and closed time and its adjustable air intake sleeve. The two potentiometers controlling the open and closed time can be set to a maximum of 30 seconds each. The air intake sleeve can be adjusted to intake between 20 and 120 CFM of air at 15 inches Hg. View the complete Sentinel Air Injector Parts & Maintenance Manual as a PDF. Go here. One of the unique features of the Model 465 enables the user to visually set the air intake to specific flow, from 20 CFM to 120 CFM. Adjusting the intake flow of air has proven to be important in the proper creation of water slugs in the washing process. The Dairy Farmer can fine-tune his/her wash-up system by using the new Sentinel Air Injector - Model 465. Specifications:- Capacity air intake 20 to 120 CFM (200 CFM with the air intake sleeve removed).

- 1 1/2" Connecting orifice. Unit connects to system with 1 1/2" ID tubing.

- 120 Volts.

- Wall or direct mounted.

- Unit requires 5" Hg to activate.

- Shipping weight: 5 1/2 lbs.

- Replaceable filter.

Key Benefits:- Adjustable air intake for proper slug size.

- Set ON and OFF times.

- Fine tune your cleaning system.

For a copy of the Sentinel Air Injector Manual for the Model 465 click below: Sentinel Air Injector Parts & Maintenance Manual - PDF - 8 pages |